Adhesion of windowed security threads

The security thread is usually a 1-3 mm wide metallised strip that lies within the paper, as it is already introduced into the paper mass during substrate production. A variant is the window security thread, which lies open in sections by reducing the thickness of the paper as with a watermark. This is usually 3-6 mm wide and can also be provided with additional optical or invisible properties.

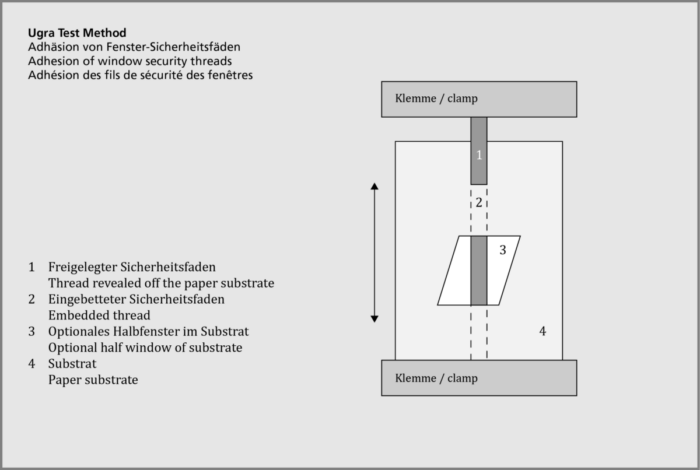

The test method is adapted on the basis of the International Standard ISO 1924-2. This part of the ISO 1924 standard specifies a method for measuring the tensile strength, elongation at break and energy absorption in tension of paper and board using a testing machine with a constant elongation rate (20 mm/min). The adhesion of the window security thread is determined on the basis of this tensile test.

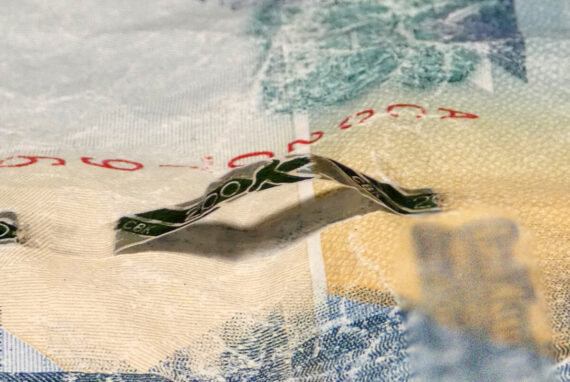

In experimental tests, it was observed that the thread broke before it could be completely pulled out of the substrate. In this case, the adhesion between the substrate and the thread was equal to or greater than the tensile force, required to break the thread (layer structure based on PET film). If, on the other hand, the thread can be pulled completely out of the substrate, then the

shear strength is determined as the measure of the adhesion between substrate and security thread. The adhesion between substrate and security thread is the decisive factor in the manufacturing

process, i.e. the embedding of the thread in the substrate, in order to achieve a long-lasting bond between these two elements.

The definition for this is: Adhesion describes the adhesive forces at the contact surfaces of two different or identical substances. In the case of the security thread, adhesion represents the adhesive force between the adhesive and the substrate. A high adhesion of the adhesive therefore guarantees a particularly good adhesion to the substrate.

- CLIENT Central Banks, Banknote Printers, Paper Manufacturers

- CATEGORY Security printing

- TAGS Adhesion , Banknotes , Durability , Security Threads

English

English  Français

Français  Deutsch

Deutsch